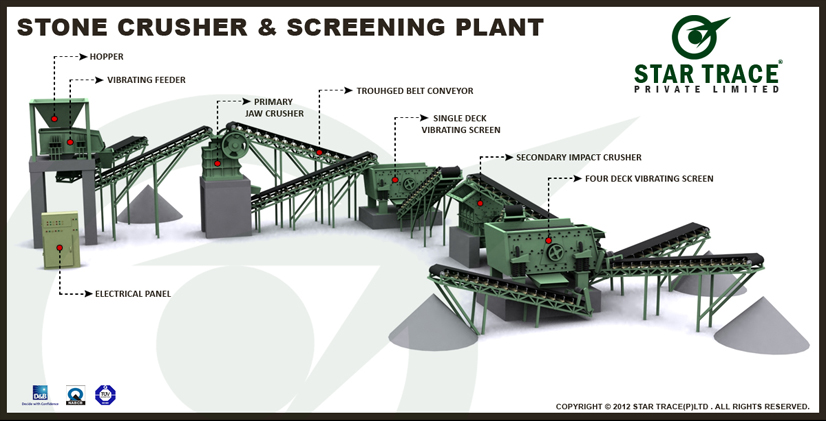

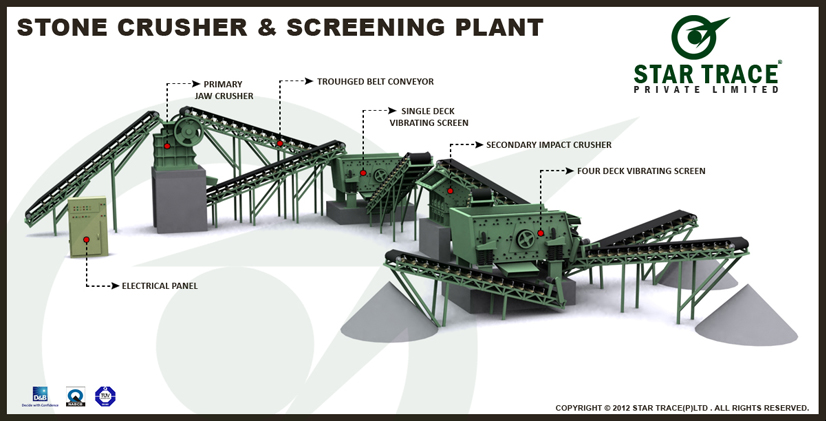

Stone Crushing & Screening Plant

Star Trace offers turnkey solutions for stone crushing & screening plants. We are one of the leading project suppliers for stone crushing & screening plant and we work closely with our customers to fulfill their specific needs for a customized packaged solution. Specialized in the fabrication of these machines for 25 years and this enables us to be in a leading position in the field of stone crushing & screening plant & equipment.

Grizzly Feeders

The Grizzly Feeder is suitable to feed primary jaw crushers, selecting the large sizes which require primary crushing, the smaller sizes, and any fines which must be eventually rejected.

The Grizzly vibro feeder consists of a very large vibrating body made of thick plate, with inside lining of anti-abrasive plate.

The Grizzly vibro feeder is driven by two or four vibrating motors. The vibro feeder which may either be placed on a steel or concrete base rest on springs.

Boosting throughout of primary crushers:

- A robustly constructed range of vibratory machines extending from units 0.5m wide x 2m long up to units 1.5m x 4.5m.

- The grizzly feeders are intended primarily for use ahead of primary crushers and are designed to handle large run-of-quarry stone, take the impact of dumped loads and smooth out the flow of material to the crusher.

- All models of grizzly vibro feeders have a flat reinforced impact area followed by a sloping grizzly bar section.

- The longer grizzly feeders are fitted with two stepped, grizzly bar sets. Replaceable wear sections of mild steel, manganese steel or rubber are fitted depending on the duty specified.

Jaw Crusher

The crushing chamber of Jaw Crusher is composited by stationary jaw and movable jaw.The crushing work simulates the movement of animals which use two jaw crushers to crush materials.

Jaw Crusher is widely used in quarry, mining, metallurgy industry, building material, highway, railway and chemical industry etc.

The largest compression resistance of the material to be crushed is 320m pa. It is ideal for the primary crushing. It features high reduction ratio, easy operation, simple construction, repeatable performance, easy maintenance and low consumption.

Impact Crusher

STAR TRACE in impact crusher is a new type of high-efficiency crushing equipment. This crusher mainly consists of board hammer, impact plate, board hammer pedestal, rotor, and feed port etc. Being simple, reliable and energy-efficient, our impact crusher is one of the most frequently used rock crushers.

Features of Impact Crusher:- Large feed size and high crushing chamber are suitable to crush hard and big materials.

- Space between impact plates and hammers can be adjusted conveniently, so the shape and size of final product can be controlled.

- New type of abrasion-proof materials are used, so life of hammers, impact plates and lining plates is much longer.

- High chromium hammer and unique lining plate are suitable to crush hard stones efficiently.

Cone Crusher

STAR TRACE Cone Crusher adopts the international advanced techniques to develop this equipment.

The design of spring cone crushers structure is distinguish from traditional design and it compiles other advantage of various type of cone crusher.

So it is applicable to fine crush of superfine crush various ores, rocks, slag and refractories.

To adopt the techniques of concave and mantle after machining process to connecter with cone surface to instead the anciently complicate techniques, Star Trace cone crusher raise efficiency in rock crushing.

It has overload hydraulic cavity and refrigeration lubricating system, which fully ensure the safety and stability of operation. It is widely used in metallurgical mining, architectural, rock & railway etc.

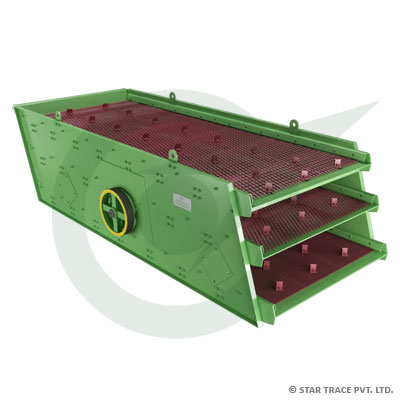

Vibrating Screen

The type universal Vibro Screen is a new generation vibratory screening machine characterized by low profile, efficient protection of support structure from vibrating masses and virtually noiseless operation.

The various versions of these Vibro Screens permit its use for wet and dry screening, coarse and fine separations and are widely used in steel mills, mineral beneficiation plants, chemical, mining, food and fertilizer industries, coal preparation plants and many others.

The standard range of screens from 300x900mm to 3000x9000mm in single and multi deck configuration.

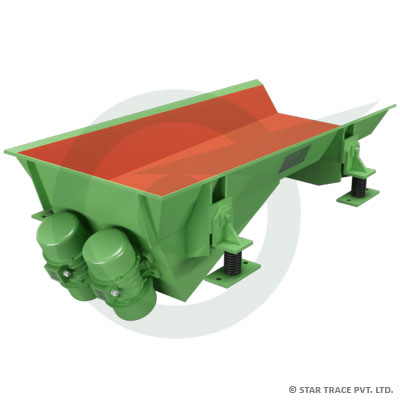

Vibrating Feeder

STAR TRACE Heavy–Duty Vibro Motor Powered Vibratory Feeder is a high frequency reciprocating machine of heavy duty capable on conveying bulk material from storage to processing or between processes at a continuous controlled rate of flow.

Thus Vibrating feeders are used in processing industries for handling all types of materials such as hot, damp, lumps, dusty or abrasive for various functions like flow of material from storage, proportioning blending, packaging, mixing, weighing, sprinkling, screening, scalping, crushing, washing, drying, heating, cooling, dusting, spreading, batching and etc.

Belt Conveyors

STAR TRACE takes the pleasure to introduce itself as one of the top most manufacturing, exporting and supplying units of Belt Conveyors based in India.

Designed to perfection, these belt conveyors are widely used in diverse industrial applications. We make use of good quality raw materials for manufacturing of these belt conveyors.

Thus our Belt Conveyors provide reliable performance and are very durable too. Made available in varied specifications, these belt conveyors are very affordable.

Applications- E-waste recycling plant

- Mining

- Metallurgy

- Coal industries